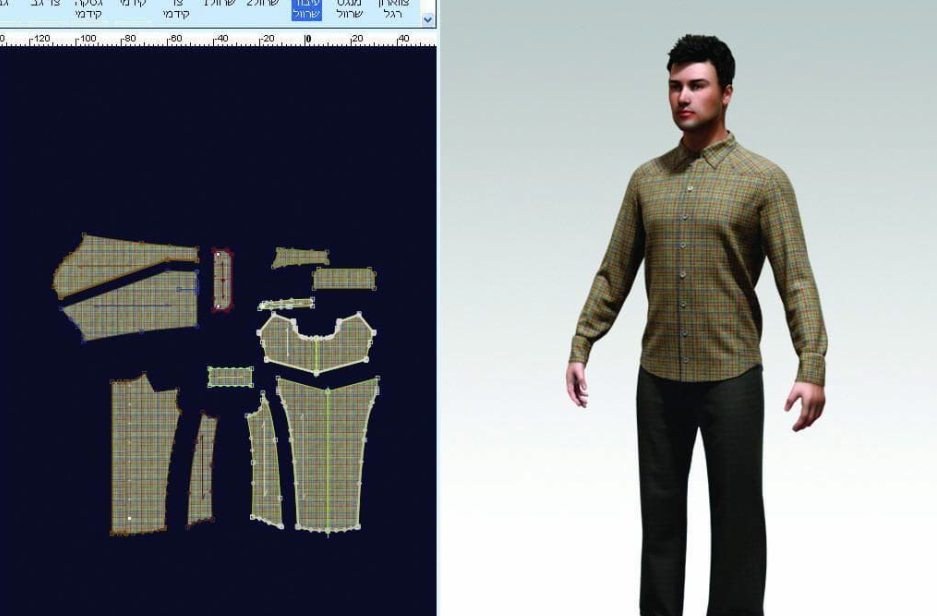

In the past, visualizing how a flat pattern would drape on the body required experience, intuition, and several physical samples. Today, 3D CAD models eliminate the guesswork by allowing designers to construct garments in a three-dimensional space before cutting a single piece of fabric. These models bring realism and interactivity into the design room, enabling designers to rotate, simulate, and adjust garments as if they were working with real fabric on a live model.

This technology is especially valuable for pattern makers, who need to balance aesthetic design with fit and function. With 3D CAD models, they can check how seams align, where tension occurs, and how different fabrics affect the silhouette. Instead of creating and correcting multiple physical muslins, they can test those variables virtually. The result is a more efficient process and far fewer production setbacks.

The interactivity of 3D CAD models also benefits collaboration. Designers and manufacturers can view the same garment, in real time, from different locations and provide feedback immediately. This minimizes the delays often caused by miscommunication or unclear visual references. By sharing detailed 3D models, teams can align their expectations, make faster decisions, and ensure better outcomes during sampling and production.

Brands seeking to innovate their fit process find particular value in 3D simulation. Standard fit sessions can now include digital avatars with custom body measurements, allowing for inclusive design considerations before cutting fabric. CAD design tools supporting 3D construction enable more accurate sizing across regions and body types, which leads to greater customer satisfaction and fewer returns.

Working with 3D CAD models also prepares fashion brands for virtual commerce and augmented reality applications. As digital wardrobes and virtual try-on technology expand, having production-grade 3D garment files becomes a competitive advantage. It enables content creation, digital marketing, and customer interaction to stem from the same files used in the design and production process.

The move from flat to form is not just technical—it’s transformative. By adopting 3D CAD models, fashion professionals gain the ability to test, refine, and perfect their garments in a space where cost and waste are reduced, and where every idea has the potential to be realized more accurately than ever before.